1.3355 / T1 / SKH2 Hot Rolled High Speed Tool Steel For Making Cutting Tools

Equivalent grades:

| GB |

DIN |

AISI |

JIS |

| W18Cr4V |

1.3355 |

T1 |

SKH2 |

Chemical Composition(%):

| C |

Si |

Mn |

Cr |

Mo |

V |

W |

Ni+Cu |

p |

s |

| 0.70-0.80 |

0.20-0.40 |

0.10-0.40 |

3.80-4.40 |

≤0.30 |

1.00-1.40 |

17.50-19.00 |

≤0.50 |

≤0.030 |

≤0.030 |

Available size(mm):

| Flat Bar Size(mm) |

Round bar Size(mm) |

| Thickness |

Width |

Length |

Diameter |

Length |

| 10-200 |

155-2200 |

2000-6000 |

20-200 |

3000-6000 |

Recommend heat treatment:

| Quenching |

Tempering |

| Heating temperature/℃ |

Cooling way |

Hardness (HRC) |

Tempering temperature/ºC |

Tempering number |

Hardness

(HRC) |

| First preheating |

Second preheating |

Last heating |

| 500-650 |

800-840 |

1270-1280 |

Air Cooling |

67-70 |

550-570 |

3 |

≥63 |

Applications:

Tool industry: scraper, hobbing knife, iron knife, drill etc.

Small cut tool with complex shape.

Feature:

1,High hardness, high red hardness and high temperature hardness, easy to grinding.

2,The application of the tool to work at a temperature of 600℃ can still keep cutting performance, such as vehicles, planing, milling, reaming, broach, drill, tap, die cutter and gear etc.

3,Suitable for processing soft or medium hardness (less than 300 ~ 320HB) material and making high temperature wear-resistant machine parts

Mould steel is used for making cold stamping die, hot forging die, die-casting mould and other die steel. Moulds are the main processing tools for manufacturing parts in industrial sectors such as mechanical manufacturing, radio meters, motors and electrical appliances.

The mould quality directly influences the quality of pressure processing technology, the precision of the product yield and production cost, and quality and service life of the mold except by reasonable structure design and machining precision, mainly by the influence of die material and heat treatment.

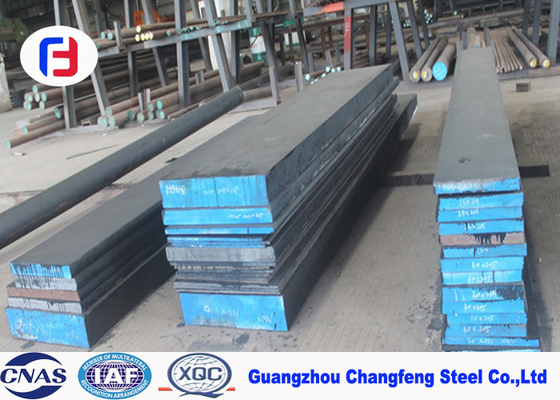

Product pictures:

Our company have introduced large-sized vertical saw machines, horizontal saw machines, milling machines, grinding machines and other advance equipments, we can export our products by wholesales and retail sales, whole plate or strip is available. All our products can meet the standards of DIN, AISI, JIS and GB, all the material should be inspected the ultrasonic, hardness and others strict inspection process before the shipment!

We can provide below service:

A. Steel plates: Cutting by bandsaw machine, milling, heat treatment, etc

B. Round bars: Cutting by bandsaw machine, peeling, grinding and turned, heat treatment, etc

Corner of factory:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!