|

Product Details:

Payment & Shipping Terms:

|

| Heat Treatment: | Prehardening | Surface Treatment: | Black Surface |

|---|---|---|---|

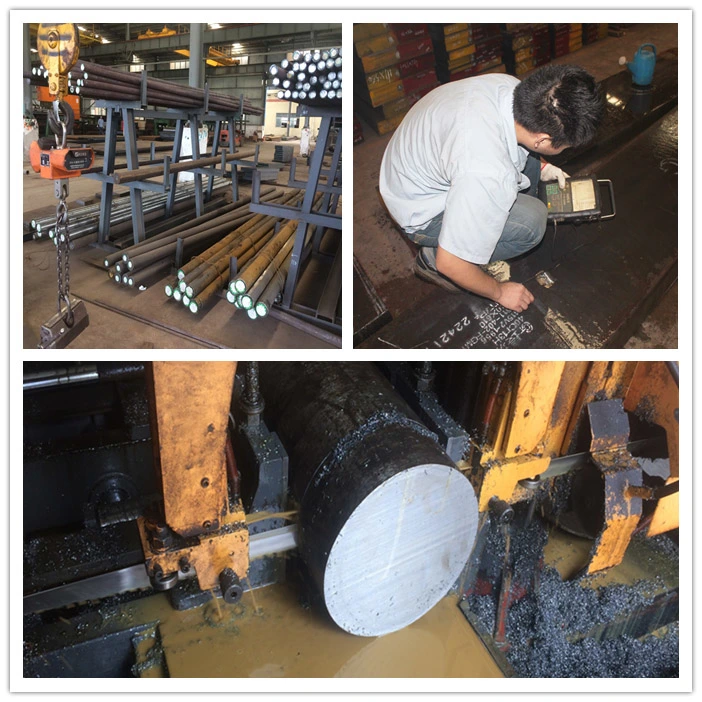

| Delivery Condition: | Forged Or Hot Rolled | Test: | SGS/Ut 100%/Element Testing |

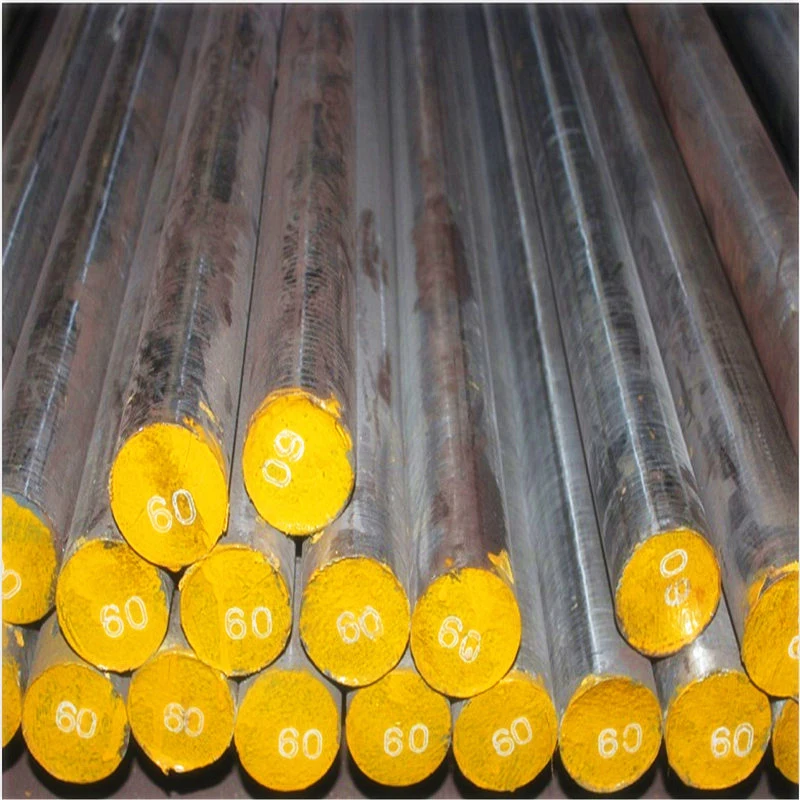

| Certificate: | ISO/MTC | Shape: | Round Bar/ Forged Bar |

| Hardness: | 28 To 34 HRC | Flaw Detection: | CC / DD/ EE |

| High Light: | plastic mould steel,mould steel material |

||

Round Polished Tool Plastic Prehardening Injection Mold Steel P20 3Cr2Mo 1.2311

1. Introduction

P20 is an internationally widely used plastic mould steel, its good mechanical properties, high hardenability can make Larger cross-section steel to obtain more uniform hardness, and this steel has good polishing performance and high mold surface finish.

When using this steel mold, usually make prehardening treatment to make the hardness reach HRC28 ~ 34 (pre-hardened).

2. Standard

GB/T 1299-1985

3. Similar grade

P 20, 1.2311,PDS-3, 3Cr2Mo

4. Chemical elements(GB/T1299-20000)%

| C | Si | Mn | P | S | Cr | Mo | Ni |

| 0.28-0.4 | 0.2-0.8 | 0.6-1 | ≤0.03 | ≤0.03 | 1.4-2 | 0.3-0.55 | 0.85-1.15 |

5. Available size

| Round | Diameter | Length | |

| 10mm-350mm | 3000mm-6000mm | ||

6. Feature

1.Pure steel vacuum degassing refining process for polishing or etch processing plastic mold

2.Pre-hardened state of supply, without heat treatment can be used directly in the mold, shorten the construction period.

3.By forging rolling processing, compact structure, 100% ultrasonic testing, non-porous, needle defects.

4.For the production of plastic mold and die casting low melting point metal mold material.

5.This steel has good machinability and mirror polishing properties.

6.Hardness:285-330HB(30-36HRC)

7.Good dimensional stability

8.With long service life,Mold die life up to 50W times

7. Application

1.Main part of overloading mold

2.Thermoplastic injection molding, extrusion dies

3.Commonly used in the manufacture of TV cabinet, washing machine, refrigerator shells, buckets, etc.

8. Our service

Contact Person: Ms. Echo

Tel: +86 18148729336

Fax: +86-020-8251-5866