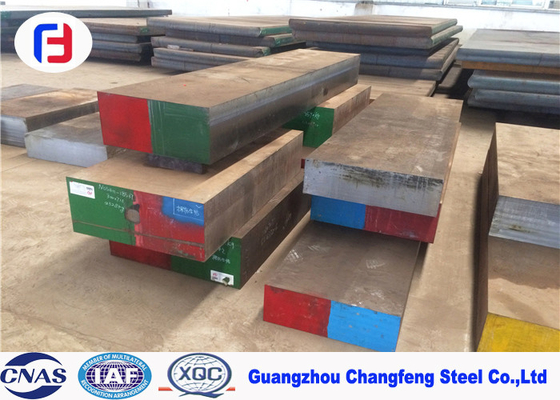

Forged Tooling Hot Work Tool Steel SKT4 / 1.2713 / L6 Used For Large Molds

Hot work tool steel with lower content of alloy elements. It is also the traditional hammer forging die steel.

It has good toughness, strength and wear resistance, hardenability, and 300 * 300 * 400mm workpiece can be fully quenched.

The utility model is suitable for producing large and medium-sized hammer forging dies (>400mm) with complicated shape and heavy impact load.

Chemical Composition(%)

| Grade |

C |

Si |

Mn |

Cr |

Mo |

P |

S |

Ni |

V |

| SKT4 |

0.50-0.60 |

≤0.4 |

0.50-0.80 |

0.50-0.80 |

0.15-0.40 |

≤0.03 |

≤0.03 |

1.40-1.80 |

- |

1, Features:

1) Heat resistant wear-resistant forged steel, excellent impact resistance, with proper hardness and good toughness.

2) The composite has good mechanical properties and high hardenability, and can make the steel with larger section size obtain a more uniform hardness.

3) Good optical rotation performance is made on the surface of the mold with low roughness value of 90.

4) Quenching and tempering treatment, hardness of 52 ~ 62HRC (pre hardening),

5) Can be used directly after cold processing into mold, ensure the use of the mold performance, but also to avoid the heat treatment caused by the deformation of the mold.

2, Application:

1) The steel is used to make all kinds of big and medium hot forging dies

2) Suitable for all kinds of medium and large hammer forging dies with complex shape and heavy impact load

3) A large forging die requiring better toughness than 5CrMnMo.

3, Recommend heat treatment

| Quenching |

Tempering |

| Heating temperature/ºC |

Cooling way |

Hardness (HRC) |

Tempering temperature |

Tempering number |

Hardness |

| /ºC |

(HRC) |

| First preheating |

Last heating |

|

|

|

|

|

| 600-650 |

830-860 |

Oil Cooling |

52-62 |

150-180 |

1 |

53-58 |

4, Process: EAF + LF + VD + Forged + Heat Treatment (optional)

5, Payment: 30% advance by T/T; Balance pay before the shipment against shipping documents or irrevocable LC at sight.

6, Delivery condition: For abundant stock, 15-20 days. For customized products, 30-50 days.

7, More about Hot Work Tool Steel

Hot work tool steels are designed to work at high temperatures. Its chemical and physical properties are not found in carbon and structural steels. The material properties required to work in such difficult conditions are listed below:

• Hot wear resistance

• Erosion resistance

• Oxidation resistance

• Thermal fatigue and hot cracking resistance

• Thermal shock resistance

• Temper strength

• Softness and toughness

• Excellent machinability

• High thermal conductivity

• Low coefficient of friction

These features are obtained after a balanced chemical analysis and a specific production process.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!